Hubei Hannas Tech Co.,Ltd-Professional Piezoceramic Elements Supplier

Hot Keywords:

- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

| Availability: | |

|---|---|

| Quantity: | |

PHA-64-05FC-F

Piezohannas

PHA-64-05FC-F

64KHz Ultrasonic Level Transducer for Liquid Level Sensors

Items | Technical Parameters | Image | |

Name | 64KHz anti-corrosive transducer C type (split types) |

| |

Model | PHA-64-05FC-F | ||

Frequency | 64KHz±5% | ||

Detection Distance | 0.4~5m | ||

Minimum Parallel lmpedance | 1700Ω±20% | ||

Capacitance | 2500pF±20% @1KHz | ||

Sensitivity | Driving Voltage::800Vpp,Distance:0.6m, Echo Amplitude:150mV | ||

Operating Voltage | Peak Voltage<1500VPP | ||

Operating Temperature | -40~+80℃ | ||

Pressure | ≤3Kilos or 0.3MPa | ||

Angle | (Beamwidth) Half-power Beam Width@-3dB:4°±2, Sharp Angle:10°±4 | ||

Housing Material | PTFE

| ||

Usage | Ultrasonic level gauge,Monitoring,Crashproof, Security | ||

Installation Dimension | The lifting thread:M38×1.5,Bottom with thread :M78×2 | ||

Protection Level | IP68 | ||

Weight | 1160g±5%(Length:10M) | ||

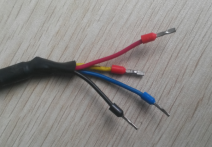

Wiring Instructions | separated type(four-wire):Red: transducer+、white: transducer-、blue,black:temperature sensor(MF58); separated type(Three-wire):Red: transducer+、blue:temperature sensor+、black: Common Line- | ||

Admittance Curve | Product Structure Diagram | ||

|

| ||

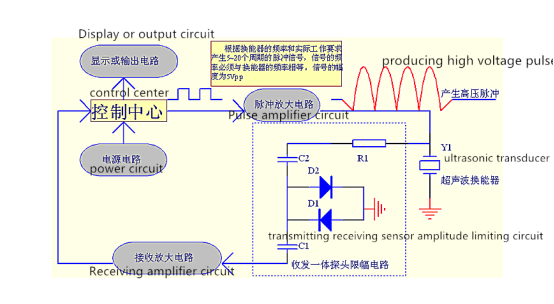

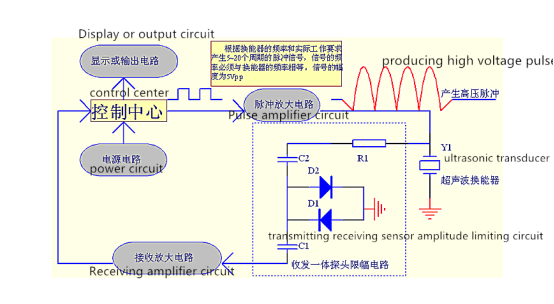

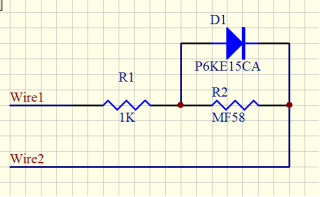

Block diagram of ultrasonic transducer :

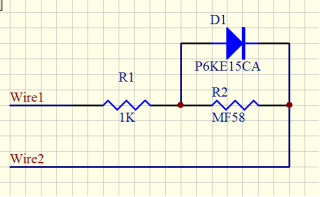

Schematic Diagram of Temperature Sensor:

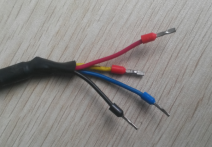

Split type Cable instruction:

Standard wire is 10M, signal will attenuate 6dB for each 50M increasing of wire.

1. Three core wiring instructions:

Red: transducer +

Blue: temperature sensor +

Black: public -

2.Four core wiring instructions:

Red: transducer +

Yellow: transducer -

Blue, black: temperature sensor +

Ultrasonic Level Transducer Application:

A wide range of level sensor measurement systems are made available for addressing the various parameters such as a wide range of applications, high-accuracy needs, and system installation requirements and practices. Measurement technologies are made available in different versions to address a wide range of measurement needs, or to address a specific application.

Liquid level sensors are termed as the sensors used for detecting liquid levels or interfaces between liquids such as water and oil or solids and liquids. These sensors can also be defined as transducers or as integrated systems with instrumentation and control capabilities. This type of liquid level sensor is one of the most important sensors and plays a vital role in variety of industrial and consumer applications.

64KHz Ultrasonic Level Transducer for Liquid Level Sensors

Items | Technical Parameters | Image | |

Name | 64KHz anti-corrosive transducer C type (split types) |

| |

Model | PHA-64-05FC-F | ||

Frequency | 64KHz±5% | ||

Detection Distance | 0.4~5m | ||

Minimum Parallel lmpedance | 1700Ω±20% | ||

Capacitance | 2500pF±20% @1KHz | ||

Sensitivity | Driving Voltage::800Vpp,Distance:0.6m, Echo Amplitude:150mV | ||

Operating Voltage | Peak Voltage<1500VPP | ||

Operating Temperature | -40~+80℃ | ||

Pressure | ≤3Kilos or 0.3MPa | ||

Angle | (Beamwidth) Half-power Beam Width@-3dB:4°±2, Sharp Angle:10°±4 | ||

Housing Material | PTFE

| ||

Usage | Ultrasonic level gauge,Monitoring,Crashproof, Security | ||

Installation Dimension | The lifting thread:M38×1.5,Bottom with thread :M78×2 | ||

Protection Level | IP68 | ||

Weight | 1160g±5%(Length:10M) | ||

Wiring Instructions | separated type(four-wire):Red: transducer+、white: transducer-、blue,black:temperature sensor(MF58); separated type(Three-wire):Red: transducer+、blue:temperature sensor+、black: Common Line- | ||

Admittance Curve | Product Structure Diagram | ||

|

| ||

Block diagram of ultrasonic transducer :

Schematic Diagram of Temperature Sensor:

Split type Cable instruction:

Standard wire is 10M, signal will attenuate 6dB for each 50M increasing of wire.

1. Three core wiring instructions:

Red: transducer +

Blue: temperature sensor +

Black: public -

2.Four core wiring instructions:

Red: transducer +

Yellow: transducer -

Blue, black: temperature sensor +

Ultrasonic Level Transducer Application:

A wide range of level sensor measurement systems are made available for addressing the various parameters such as a wide range of applications, high-accuracy needs, and system installation requirements and practices. Measurement technologies are made available in different versions to address a wide range of measurement needs, or to address a specific application.

Liquid level sensors are termed as the sensors used for detecting liquid levels or interfaces between liquids such as water and oil or solids and liquids. These sensors can also be defined as transducers or as integrated systems with instrumentation and control capabilities. This type of liquid level sensor is one of the most important sensors and plays a vital role in variety of industrial and consumer applications.

Products | About Us | News | Markets and Applications | FAQ | Contact Us