Hubei Hannas Tech Co.,Ltd-Professional Piezoceramic Elements Supplier

Hot Keywords:

- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

| Availability: | |

|---|---|

| Quantity: | |

PR1000K052

Piezohannas

PR1000K052

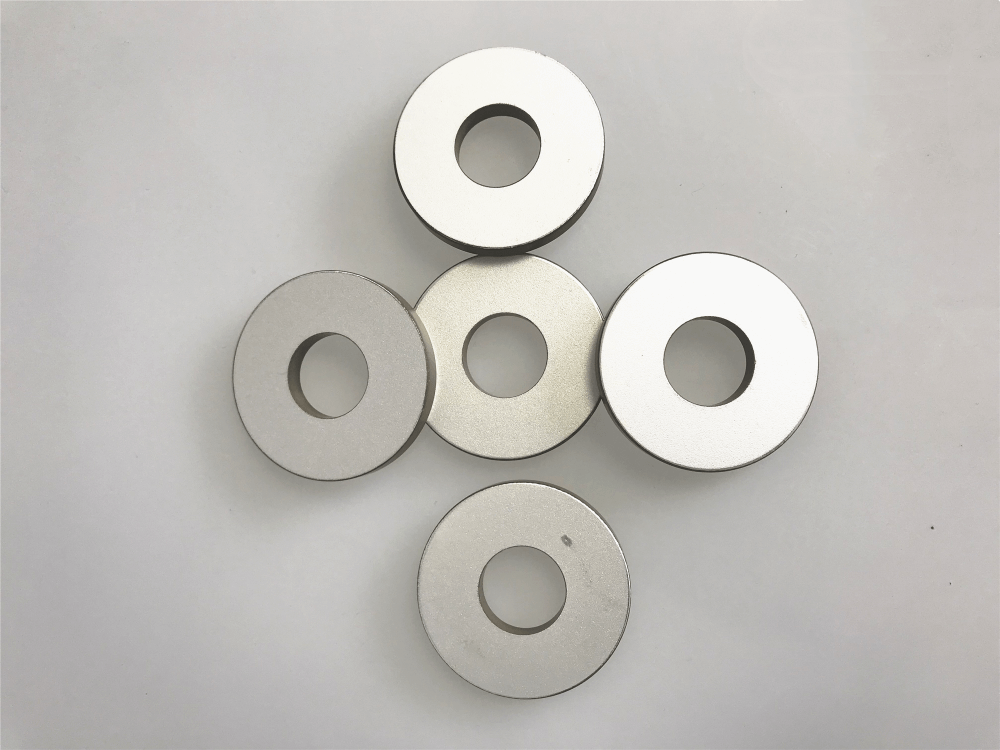

Pzt8 Material Piezoelectric Ring Crystal for Ultrasonic textile Cutting

WuHan Piezohannas Tech.Co .,Ltd is a manufactuer of piezoelectric ceramics ,ultrasonic transducers with strong technology force.With a quality management system and research & development sector,our products are extensively used in most applications.

1.Product Description

Dimension : OD60mm xID30mm x Thi10mm

Material: Pzt4 or Pzt8

Range Of piezo ceramic ring

External diameter: 5.0 - 100mm

Internal diameter :(2.0 - 35mm)

Thickness : (0.2 - 15mm)

Dimension(mm) | Capacity C(pF) | Weak Field Dissipation Tgδ(12v) | Strong Fied Dissipation Tgδ(400v) | Radial Frequency Fr(KHz) | ResonanceImpedance | Thick Frequency Ft(KHz) | Coupling Modulus Kr(%) | |

Φ10xΦ5x2 | 240±10% | ≤0.5% | ≤1.0% | 153±5% | ≤15 | 1020 | ≥45 | |

Φ16xΦ8x4 | 340±10% | ≤0.5% | ≤1.0% | 95.8±5% | ≤20 | 512 | ≥45 | |

Φ25xΦ10x4 | 935±10% | ≤0.5% | ≤1.0% | 65.5±5% | ≤15 | 512 | ≥45 | |

Φ30xΦ10x5 | 1150±10% | ≤0.5% | ≤1.0% | 58.4±5% | ≤15 | 410 | ≥45 | |

Φ32xΦ15x5 | 1080±10% | ≤0.5% | ≤1.0% | 49.2±5% | ≤15 | 410 | ≥45 | |

Φ35xΦ15x5 | 1430±10% | ≤0.5% | ≤1.0% | 45.5±5% | ≤15 | 410 | ≥45 | |

Φ38xΦ15x5 | 1750±10% | ≤0.5% | ≤1.0% | 43.4±5% | ≤15 | 410 | ≥46 | |

Φ40×Φ12×5 | 2070±12.5% | ≤0.5% | ≤1.0% | 45.9 | ≤15 | ≥46 | ||

Φ40xΦ15x5 | 1970±10% | ≤0.5% | ≤1.0% | 42.8±5% | ≤15 | 410 | ≥45 | |

Φ40×Φ20×5 | 1700±12.5% | ≤0.3 | ≤1.0% | 37.9 | ≤15 | ≥45 | ||

Φ40×Φ17×6 | 1555±12.5% | ≤0.3 | ≤1.0% | 40.5 | ≤15 | ≥45 | ||

Φ42xΦ15x5 | 2200±10% | ≤0.5% | ≤1.0% | 40±5% | ≤15 | 410 | ≥45 | |

Φ42xΦ17x5 | 2110±10% | ≤0.5% | ≤1.0% | 38.8±5% | ≤15 | 410 | ≥45 | |

Φ45xΦ15x5 | 2580±10% | ≤0.5% | ≤1.0% | 38.1±5% | ≤15 | 410 | ≥46 | |

Φ50xΦ17x5 | 3160±10% | ≤0.5% | ≤1.0% | 34.8±5% | ≤15 | 410 | ≥45 | |

Φ50xΦ17x6 | 2430±10% | ≤0.5% | ≤1.0% | 34.8±5% | ≤15 | 315 | ≥45 | |

Φ50×Φ20×6 | 2490±12.5% | ≤0.3 | ≤1.0% | 33.2 | ≤15 | ≥45 | ||

Φ50×Φ27×6 | 2100±12.5% | ≤0.3 | ≤1.0% | 29.3 | ≤15 | ≥45 | ||

Φ60×Φ30×10 | 1922±12.5% | ≤0.3 | ≤1.0% | 25.3 | ≤15 | ≥45 | ||

Not only non-woven and textile fabrics, but also various foods can be precisely and cleanly separated or cut by ultrasound.Depending on application, cutting can be performed vertically, horizontally or continuously (roll seam sonotrodes) with the appropriate sonotrode design. Sonotrodes used as cutting tools suffer comparatively low wear. Because they are cold, as in the case of ultrasonic welding and punching, a wide variety of materials can be efficiently processed. Examples of this in the food industry are various types of cheese, bakery products and confectionery, dough or deep frozen products. The respective sonotrodes divide the food precisely with the help of ultrasonic oscillations. Cutting itself is due to the reduced force required by the vibration of the cutting tool easier than with conventional knives. The foods are therefore not deformed by compression or squashing.

In the textile sector, ultrasonic cutting is distinguished by the fact that the cut edges of the non-woven or fabric do not fray. Instead, they are sealed or fused by ultrasonic technology. Besides which, during cutting desirable material embossing occurs along the cut edges, making the material thinner.

5. Applications Image:

![VE]G`{G627NY8RD{_QT0X4](http://5krorwxhlkpmrik.leadongcdn.com/cloud/iiBqnKjlRilSimiorqio/VE-G-G627N.png)

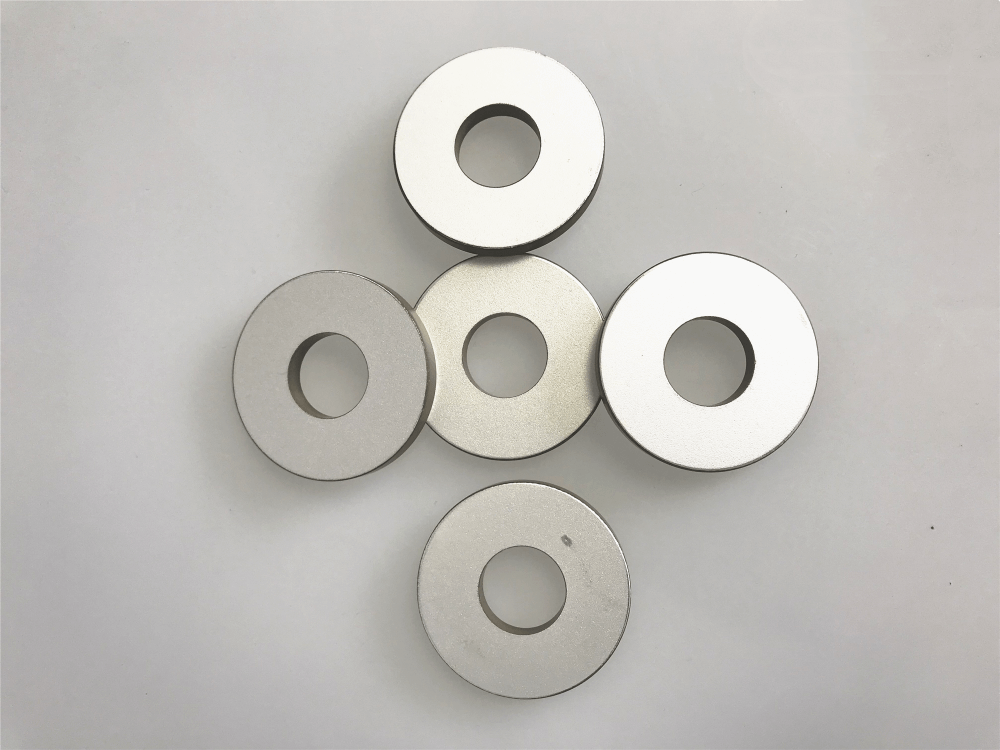

Pzt8 Material Piezoelectric Ring Crystal for Ultrasonic textile Cutting

WuHan Piezohannas Tech.Co .,Ltd is a manufactuer of piezoelectric ceramics ,ultrasonic transducers with strong technology force.With a quality management system and research & development sector,our products are extensively used in most applications.

1.Product Description

Dimension : OD60mm xID30mm x Thi10mm

Material: Pzt4 or Pzt8

Range Of piezo ceramic ring

External diameter: 5.0 - 100mm

Internal diameter :(2.0 - 35mm)

Thickness : (0.2 - 15mm)

Dimension(mm) | Capacity C(pF) | Weak Field Dissipation Tgδ(12v) | Strong Fied Dissipation Tgδ(400v) | Radial Frequency Fr(KHz) | ResonanceImpedance | Thick Frequency Ft(KHz) | Coupling Modulus Kr(%) | |

Φ10xΦ5x2 | 240±10% | ≤0.5% | ≤1.0% | 153±5% | ≤15 | 1020 | ≥45 | |

Φ16xΦ8x4 | 340±10% | ≤0.5% | ≤1.0% | 95.8±5% | ≤20 | 512 | ≥45 | |

Φ25xΦ10x4 | 935±10% | ≤0.5% | ≤1.0% | 65.5±5% | ≤15 | 512 | ≥45 | |

Φ30xΦ10x5 | 1150±10% | ≤0.5% | ≤1.0% | 58.4±5% | ≤15 | 410 | ≥45 | |

Φ32xΦ15x5 | 1080±10% | ≤0.5% | ≤1.0% | 49.2±5% | ≤15 | 410 | ≥45 | |

Φ35xΦ15x5 | 1430±10% | ≤0.5% | ≤1.0% | 45.5±5% | ≤15 | 410 | ≥45 | |

Φ38xΦ15x5 | 1750±10% | ≤0.5% | ≤1.0% | 43.4±5% | ≤15 | 410 | ≥46 | |

Φ40×Φ12×5 | 2070±12.5% | ≤0.5% | ≤1.0% | 45.9 | ≤15 | ≥46 | ||

Φ40xΦ15x5 | 1970±10% | ≤0.5% | ≤1.0% | 42.8±5% | ≤15 | 410 | ≥45 | |

Φ40×Φ20×5 | 1700±12.5% | ≤0.3 | ≤1.0% | 37.9 | ≤15 | ≥45 | ||

Φ40×Φ17×6 | 1555±12.5% | ≤0.3 | ≤1.0% | 40.5 | ≤15 | ≥45 | ||

Φ42xΦ15x5 | 2200±10% | ≤0.5% | ≤1.0% | 40±5% | ≤15 | 410 | ≥45 | |

Φ42xΦ17x5 | 2110±10% | ≤0.5% | ≤1.0% | 38.8±5% | ≤15 | 410 | ≥45 | |

Φ45xΦ15x5 | 2580±10% | ≤0.5% | ≤1.0% | 38.1±5% | ≤15 | 410 | ≥46 | |

Φ50xΦ17x5 | 3160±10% | ≤0.5% | ≤1.0% | 34.8±5% | ≤15 | 410 | ≥45 | |

Φ50xΦ17x6 | 2430±10% | ≤0.5% | ≤1.0% | 34.8±5% | ≤15 | 315 | ≥45 | |

Φ50×Φ20×6 | 2490±12.5% | ≤0.3 | ≤1.0% | 33.2 | ≤15 | ≥45 | ||

Φ50×Φ27×6 | 2100±12.5% | ≤0.3 | ≤1.0% | 29.3 | ≤15 | ≥45 | ||

Φ60×Φ30×10 | 1922±12.5% | ≤0.3 | ≤1.0% | 25.3 | ≤15 | ≥45 | ||

Not only non-woven and textile fabrics, but also various foods can be precisely and cleanly separated or cut by ultrasound.Depending on application, cutting can be performed vertically, horizontally or continuously (roll seam sonotrodes) with the appropriate sonotrode design. Sonotrodes used as cutting tools suffer comparatively low wear. Because they are cold, as in the case of ultrasonic welding and punching, a wide variety of materials can be efficiently processed. Examples of this in the food industry are various types of cheese, bakery products and confectionery, dough or deep frozen products. The respective sonotrodes divide the food precisely with the help of ultrasonic oscillations. Cutting itself is due to the reduced force required by the vibration of the cutting tool easier than with conventional knives. The foods are therefore not deformed by compression or squashing.

In the textile sector, ultrasonic cutting is distinguished by the fact that the cut edges of the non-woven or fabric do not fray. Instead, they are sealed or fused by ultrasonic technology. Besides which, during cutting desirable material embossing occurs along the cut edges, making the material thinner.

5. Applications Image:

![VE]G`{G627NY8RD{_QT0X4](http://5krorwxhlkpmrik.leadongcdn.com/cloud/iiBqnKjlRilSimiorqio/VE-G-G627N.png)

Products | About Us | News | Markets and Applications | FAQ | Contact Us