Hubei Hannas Tech Co.,Ltd-Professional Piezoceramic Elements Supplier

Hot Keywords:

- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

| Availability: | |

|---|---|

| Quantity: | |

PHAU-200-01C

Piezohannas

PHAU-200-01C

Stainless Steel 200Khz Ultrasonic Transducer for Ultrasonic Gas Meter

Technical parameters:

Items | Technical Parameters | Image | |

Name | 200KHz ultrasonic transducer |

| |

Model | PHAU-200-01C | ||

Frequency | 200KHz±5% | ||

Detection Distance | 0.10~1m | ||

Minimum Parallel lmpedance | 670Ω±20% | ||

600pF±20% @1KHz | |||

Sensitivity | load driving voltage:800Vpp,Distance:0.3m, Echo Amplitude:25mV | ||

-40~+80℃ | |||

≤16Kilos or 1.6MPa | |||

(Beamwidth)Half-power Beam Width@-3dB:8.4°±10%, Sharp Angle:19.9°±10% | |||

Housing Material | titanium alloy | ||

usage | ultrasonic gas flowmeter | ||

dimensionProtection Level | IP68 | ||

Weight | 20.7g±5%(wire length:80cm) | ||

Wiring Instructions | interface: red: transducer +, white: transducer -, black: shielded wire, ( temperature sensor is optional) | ||

Admittance Curve | Product Structure Diagram | ||

|

| ||

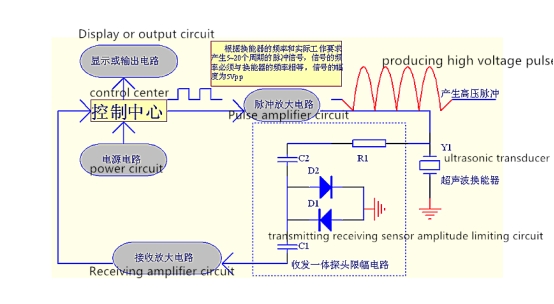

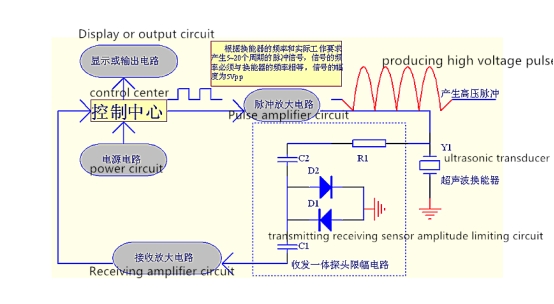

Block diagram of ultrasonic distance transducer :

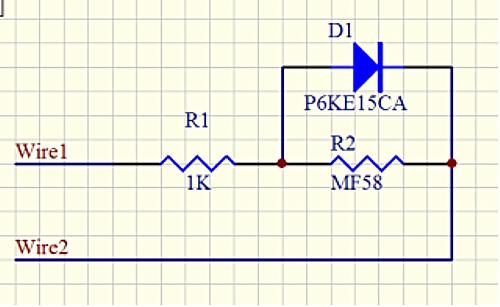

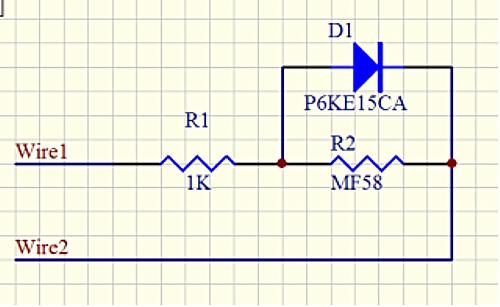

Schematic Diagram of Temperature Sensor (model: MF58_502F3470):

Integrated type Cable instruction:

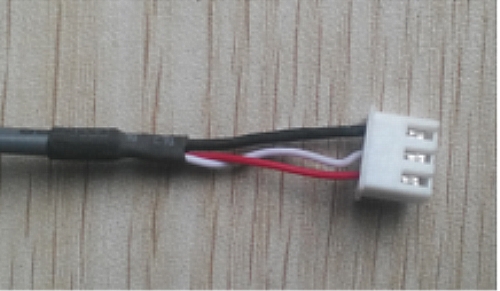

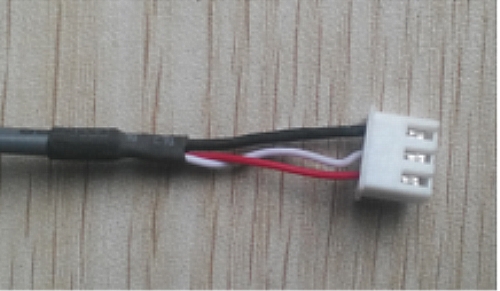

1.Wiring instruction of transducer: interface (3pin, 2.54mm terminal)

Red: transducer +

White: transducer -

Black: shielding

2.Cable Instruction of Temperature Sensor: interface (3pin, 2.0mm terminal)

Red and black are temperature sensor wiring

Split type: standard 10m cable, with each additional 50m of cable, the signal attenuation is 6dB

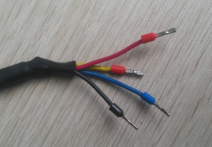

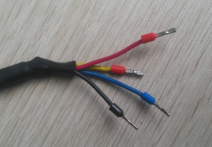

Three-core wiring instructions:

Red: Transducer +

Blue: temperature sensor +

Black: Public-

Four-core wiring instructions:

Red: Transducer +

Yellow: Transducer-

Blue, black: temperature sensor

Application for Ultrasonic Gas Flowmeter :

Industrial gas flow meters are widely utilised for liquid and water applications, it has long been accepted that clamp on gas flowmeter technology could not be applied to mass gas flow measurement primarily due to fundamental theoretical measurement limits. the transmitted sound energy is received by traditional ultrasonic transducers. However, advances in clamp on gas flow measurement technology and processing have meant that despite lower acoustic impedance levels and higher attenuation levels in most gases, a clamp on gas flow meter can now measure transit times in gases where signal-to-noise ratios are extremely low. It is now possible to measure natural gas, steam, compressed air, hydrogen, compressed air and many more using clamp on flow meters.

Stainless Steel 200Khz Ultrasonic Transducer for Ultrasonic Gas Meter

Technical parameters:

Items | Technical Parameters | Image | |

Name | 200KHz ultrasonic transducer |

| |

Model | PHAU-200-01C | ||

Frequency | 200KHz±5% | ||

Detection Distance | 0.10~1m | ||

Minimum Parallel lmpedance | 670Ω±20% | ||

600pF±20% @1KHz | |||

Sensitivity | load driving voltage:800Vpp,Distance:0.3m, Echo Amplitude:25mV | ||

-40~+80℃ | |||

≤16Kilos or 1.6MPa | |||

(Beamwidth)Half-power Beam Width@-3dB:8.4°±10%, Sharp Angle:19.9°±10% | |||

Housing Material | titanium alloy | ||

usage | ultrasonic gas flowmeter | ||

dimensionProtection Level | IP68 | ||

Weight | 20.7g±5%(wire length:80cm) | ||

Wiring Instructions | interface: red: transducer +, white: transducer -, black: shielded wire, ( temperature sensor is optional) | ||

Admittance Curve | Product Structure Diagram | ||

|

| ||

Block diagram of ultrasonic distance transducer :

Schematic Diagram of Temperature Sensor (model: MF58_502F3470):

Integrated type Cable instruction:

1.Wiring instruction of transducer: interface (3pin, 2.54mm terminal)

Red: transducer +

White: transducer -

Black: shielding

2.Cable Instruction of Temperature Sensor: interface (3pin, 2.0mm terminal)

Red and black are temperature sensor wiring

Split type: standard 10m cable, with each additional 50m of cable, the signal attenuation is 6dB

Three-core wiring instructions:

Red: Transducer +

Blue: temperature sensor +

Black: Public-

Four-core wiring instructions:

Red: Transducer +

Yellow: Transducer-

Blue, black: temperature sensor

Application for Ultrasonic Gas Flowmeter :

Industrial gas flow meters are widely utilised for liquid and water applications, it has long been accepted that clamp on gas flowmeter technology could not be applied to mass gas flow measurement primarily due to fundamental theoretical measurement limits. the transmitted sound energy is received by traditional ultrasonic transducers. However, advances in clamp on gas flow measurement technology and processing have meant that despite lower acoustic impedance levels and higher attenuation levels in most gases, a clamp on gas flow meter can now measure transit times in gases where signal-to-noise ratios are extremely low. It is now possible to measure natural gas, steam, compressed air, hydrogen, compressed air and many more using clamp on flow meters.

Products | About Us | News | Markets and Applications | FAQ | Contact Us