Hubei Hannas Tech Co.,Ltd-Professional Piezoceramic Elements Supplier

Hot Keywords:

- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

| Availability: | |

|---|---|

| Quantity: | |

PHA-200-01KC

Piezohannas

PHA-200-01KC

Low Cost Piezoelectric Ultrasonic Transducer for Ultrasonic Anemometers Sensor

Items | Technical Parameters | Image | |

Name | 200KHz ultrasonic transducer |

| |

Model | PHA-200-01KC | ||

Frequency | 200KHz±5% | ||

Detection Distance | 0.10~1.5m | ||

Minimum Parallel lmpedance | 2300Ω±20% | ||

370pF±20% @1KHz | |||

Sensitivity | Driving Voltage:800Vpp,Distance:0.3m, Echo Amplitude:40mV | ||

-40~+80℃ | |||

≤3Kilos or 0.3MPa | |||

| (Beamwidth) Half-power Beam Width@-3dB:10°±2, Sharp Angle:23°±4 | ||

Housing Material | POM | ||

Usage | anemorumbometer, gas flowmeter | ||

thread:M12*1.5 | |||

Protection Level | IP68 | ||

Weight | 8.7g±5%( Length:10cm) | ||

Wiring Instructions | integrated type:connector:Red+,White-,Black: shielded wire; temp sensor is optional | ||

Admittance Curve | Product Structure Diagram | ||

| | ||

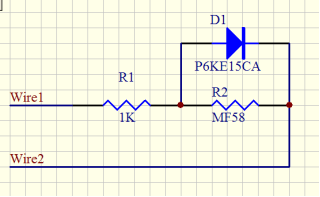

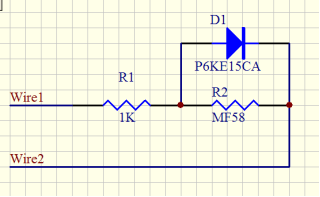

Schematic Diagram of Temperature Sensor:

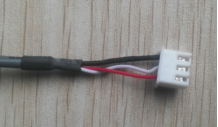

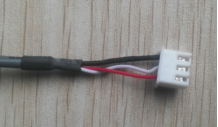

Integrated type Cable instruction:

1.Wiring instruction of transducer: interface (3pin, 2.54mm terminal)

Red: transducer +

White: transducer -

Black: shielding

2.Cable Instruction of Temperature Sensor: interface (3pin, 2.0mm terminal)

Red and black are temperature sensor wiring

Ultrasonic Anemometers Sensor Application:

An anemometer is a common instrument at a weather station. It is used to measure the wind speed and wind direction. The most common type of anemometer uses mechanical sensors consisting of three or four hemispherical cups mounted on horizontal arms on a vertical rod. As the wind blows, the cups are pushed causing the arms to rotate at a rate proportional to the wind speed. In addition, a wind vane connected to the anemometer can give the direction measurements. While the cup and vane anemometers are very popular due to their very simple design, they can be susceptible under cold and humid conditions because of their mechanical rotating parts, possibly causing the turbine to stop operating during extreme conditions. Designed without any moving parts, the ultrasonic anemometers are more reliable, maintenance free, long-lasting, and can operate in challenging weather conditions. In this article, we will review the basic working principle of an ultrasonic anemometer, and discuss about some DIY versions of ultrasonic anemometers reported by makers on the internet.

Product Image:

Low Cost Piezoelectric Ultrasonic Transducer for Ultrasonic Anemometers Sensor

Items | Technical Parameters | Image | |

Name | 200KHz ultrasonic transducer |

| |

Model | PHA-200-01KC | ||

Frequency | 200KHz±5% | ||

Detection Distance | 0.10~1.5m | ||

Minimum Parallel lmpedance | 2300Ω±20% | ||

370pF±20% @1KHz | |||

Sensitivity | Driving Voltage:800Vpp,Distance:0.3m, Echo Amplitude:40mV | ||

-40~+80℃ | |||

≤3Kilos or 0.3MPa | |||

| (Beamwidth) Half-power Beam Width@-3dB:10°±2, Sharp Angle:23°±4 | ||

Housing Material | POM | ||

Usage | anemorumbometer, gas flowmeter | ||

thread:M12*1.5 | |||

Protection Level | IP68 | ||

Weight | 8.7g±5%( Length:10cm) | ||

Wiring Instructions | integrated type:connector:Red+,White-,Black: shielded wire; temp sensor is optional | ||

Admittance Curve | Product Structure Diagram | ||

| | ||

Schematic Diagram of Temperature Sensor:

Integrated type Cable instruction:

1.Wiring instruction of transducer: interface (3pin, 2.54mm terminal)

Red: transducer +

White: transducer -

Black: shielding

2.Cable Instruction of Temperature Sensor: interface (3pin, 2.0mm terminal)

Red and black are temperature sensor wiring

Ultrasonic Anemometers Sensor Application:

An anemometer is a common instrument at a weather station. It is used to measure the wind speed and wind direction. The most common type of anemometer uses mechanical sensors consisting of three or four hemispherical cups mounted on horizontal arms on a vertical rod. As the wind blows, the cups are pushed causing the arms to rotate at a rate proportional to the wind speed. In addition, a wind vane connected to the anemometer can give the direction measurements. While the cup and vane anemometers are very popular due to their very simple design, they can be susceptible under cold and humid conditions because of their mechanical rotating parts, possibly causing the turbine to stop operating during extreme conditions. Designed without any moving parts, the ultrasonic anemometers are more reliable, maintenance free, long-lasting, and can operate in challenging weather conditions. In this article, we will review the basic working principle of an ultrasonic anemometer, and discuss about some DIY versions of ultrasonic anemometers reported by makers on the internet.

Product Image:

Products | About Us | News | Markets and Applications | FAQ | Contact Us