Hubei Hannas Tech Co.,Ltd-Professional Piezoceramic Elements Supplier

Hot Keywords:

- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

Views: 3 Author: Site Editor Publish Time: 2020-05-25 Origin: Site

In the industrial market, semiconductor chipsets play a huge role in the transformation of mechanical equipment to electromechanical or purely electronic equipment. Each market segment can be broken down into many applications, and manufacturers will design specific products for each application.

Ultrasound or ultrasound technology has been used in some civil, medical and military fields for more than 100 years. Almost everyone will use medical ultrasound technology in their lifetime. However, its most recent application case is the realization of automation in the industrial and automotive fields. We are surprised to see that this technology has taken its place in a series of truly diverse applications. The non-invasive (non-corrosive) and non-contact characteristics of ultrasonic technology make it ideal for medical, pharmaceutical, military and factory applications.

In the industrial and automotive markets, ultrasonic technology can be found for distance measurement, occupancy detection, level detection, composition analysis, flow rate measurement, parking assistance, landing assistance, and trunk opening assistance. Ultrasonic sensors, also known as ultrasonic transducers, can operate outside of frequencies that humans cannot hear, and their operating frequencies range from 20 kHz to a few megahertz.

Most ultrasonic transducers are made of piezoelectric materials, and when electrical pulses are applied, mechanical vibrations or ultrasonic waves are generated. Some transducers can also convert mechanical vibration back to electrical energy. Transducers are roughly divided into three types:

After processing the received electrical signal, you can get several relevant components suitable for industrial or automotive applications. One of the most common and important components is ultrasonic time-of-flight (TOF), which refers to the round-trip time estimate of ultrasonic waves emitted from the ultrasonic flowmeter transducer for flow measurement to the target object and then reflected back from the object to the sensor. This is the basic principle of using ultrasonic technology in smart meters to measure the flow of water, gas or heating (whether intrusive or non-intrusive), and present consumption data to consumers for easy billing.

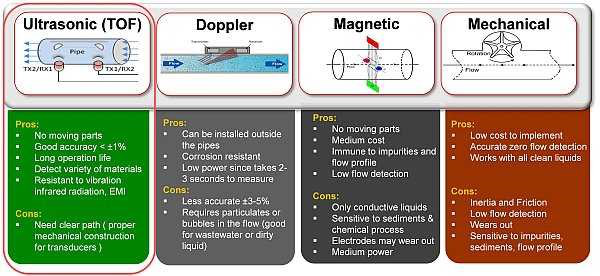

Flow measurement is the quantification of liquid or gas flow (volume or velocity). The unit of measurement is similar to liters / minute (or seconds or hours) or square meters / second. The range of flowmeters is relatively wide, from simple public instruments for household use (gas / water / heating) to industrial instruments or mixers for hazardous liquids or gases (oil, mining, wastewater treatment, paints and chemicals, etc.). Structurally, the flowmeter includes a sensor unit, a measurement unit, and a control / communication unit, each of which can be further divided into mechanical or electronic. Figure 1 compares the different types of flowmeter sensing technologies that make up the sensor unit. Ultrasonic flow meters have several advantages.

Figure 1: Comparison of liquid or gas flow sensing methods

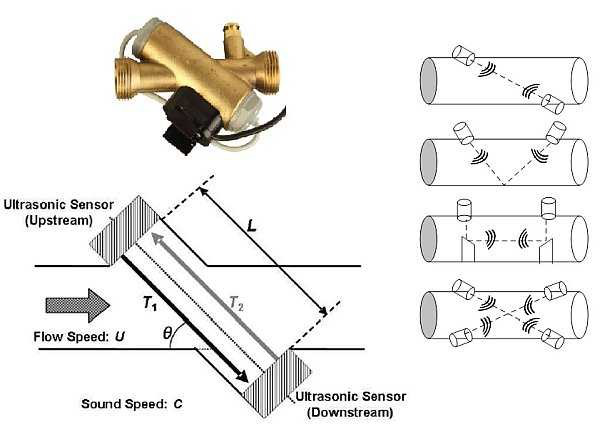

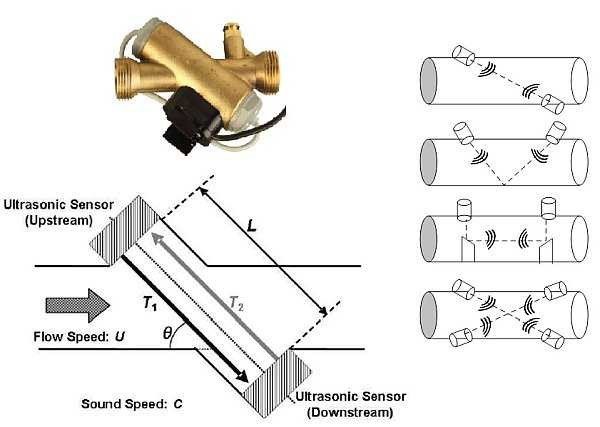

Ultrasonic flowmeter transducer using TOF or ultrasound measure flow by calculating the time difference (propagation delay) of the transmitted and received ultrasound signals. To apply it to flow measurement, designers use a pair of identical transceiver-type transducers to excite them in the upstream and downstream directions, respectively. When propagating in a direction consistent with fluid flow, ultrasonic waves propagate faster, while in a direction opposite to fluid flow, ultrasonic waves propagate slower. Therefore, at least one pair of transducers is required, but some topologies use more transducers.

Figure 2 shows a typical concept of ultrasonic flow detection, and the placement of the transducer in the pipeline can be selected.The choice of ultrasonic sensor depends on the type of medium that requires flow rate measurement. Generally, liquid sensing uses sensors with higher frequencies in the spectrum (> 1 MHz), while gaseous media uses sensors with lower frequencies (<500 kHz). In addition, the ultrasonic technology used for flow measurement requires a direct path between any two transducers, which requires careful mechanical construction design of the fluid pipeline that houses the transducer. Ultrasonic technology does not work in the presence of bubbles, because bubbles may cause significant attenuation of the ultrasound signal.

Figure 2: Examples of common topologies for ultrasonic sensing of flowmeters and installation locations in pipes

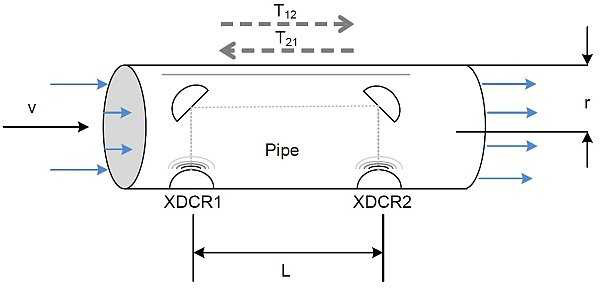

Figure 3 shows a generic piping design with the transducer placed at the bottom and reflective material to ensure that the ultrasonic signal can propagate between the transducers (XDCR1 and XDCR2 in the figure).

Figure 3: Universal flow tube with a pair of transducers installed

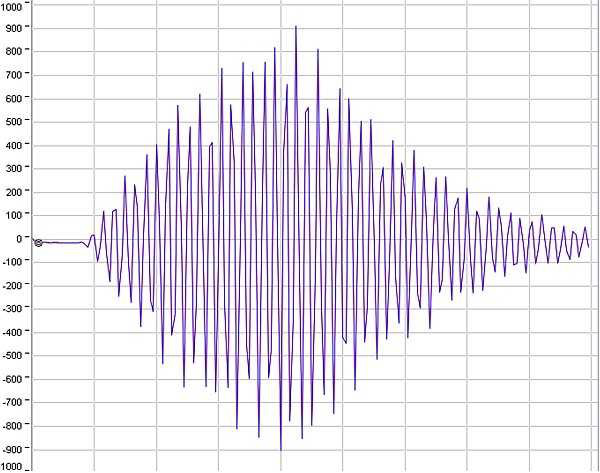

Where Δt is TOF, c is the speed of the ultrasonic signal propagating in the medium in the pipeline, v is the flow velocity, L is the propagation length of the pipeline, T12 is the propagation time upstream, and T21 is the propagation time downstream.There are several ways to determine TOF information, but all methods need to be able to process the output of the transducer.Figure4 shows a typical output.

Figure 4: Typical response of an ultrasonic transducer when it is electrically excited

The processing of this waveform provides the information needed to solve equations 1 and 2. There are several ways to process waveforms, including time-to-digital conversion (TDC), zero-crossing detection and waveform capture. Each method has advantages and disadvantages.

Chip vendors use various architectures to solve ultrasonic flow measurement problems. Some manufacturers use discrete analog components, followed by digital processors. Other manufacturers have tried to integrate analog components into digital processors to form a single-chip solution. In the waveform capture method, a fast analog circuit is used to capture the entire ultrasonic signal, and then an analog-to-digital converter is used to convert the analog signal to a digital signal, and then the digital signal processing algorithm can obtain TOF information.

Chip vendors use various architectures to solve ultrasonic flow measurement problems. Some manufacturers use discrete analog components of 100KHz ultrasonic transducer, followed by digital processors. Other manufacturers have tried to integrate analog components into digital processors to form a single-chip solution. In the waveform capture method, a fast analog circuit is used to capture the entire ultrasonic signal, and then an analog-to-digital converter is used to convert the analog signal to a digital signal, and then the digital signal processing algorithm can obtain TOF information.

Because of the technical improvements of ultrasonic transducers, making them cheaper, more accurate, smaller in size, and ubiquitous, ultrasonic technology has been widely used in flow measurement. The advanced integrated analog circuit makes it easier to capture and process the ultrasonic transducer waveform in real time, thus obtaining accurate TOF information. In addition, the ultrasonic flowmeter is more accurate, smaller in size, and has no moving parts, making it an excellent choice for manufacturers to replace mechanical flowmeters. However, manufacturers still need to carefully understand the piping design and transducer installation and positioning to ensure that all the advantages of ultrasonic technology are fully utilized in flow measurement.

Products | About Us | News | Markets and Applications | FAQ | Contact Us