| Availability: | |

|---|---|

| Quantity: | |

PZ1000K00

Piezohannas

PZ1000K00

High Sensitivity Soft Piezoelectric Ceramics Piezo Tube for Sonar

WuHan Piezohannas Tech.Co .,Ltd is a manufactuer of piezoelectric ceramics ,ultrasonic transducers with strong technology force.With a quality management system and research & development sector,our products are extensively used in most applications.

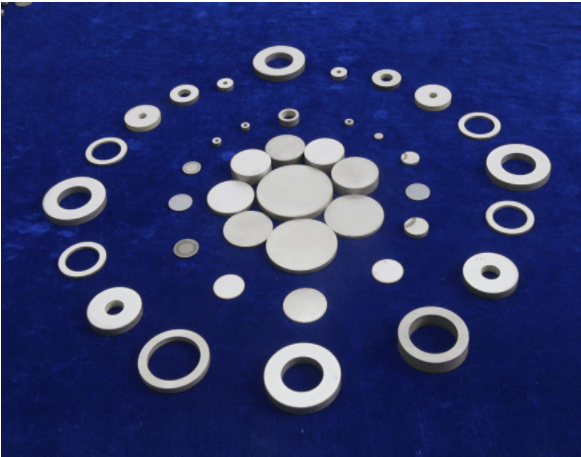

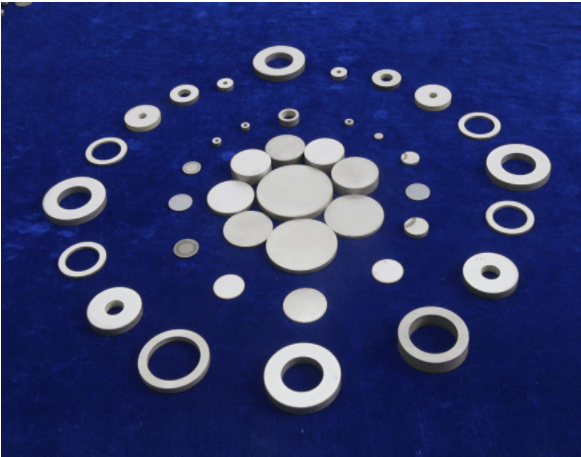

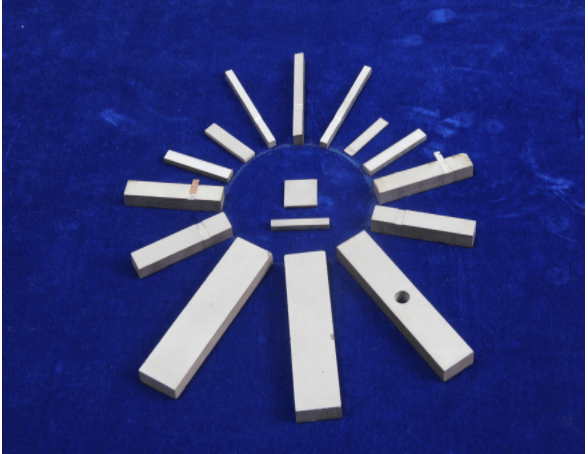

l. Piezo ceramic Description:

Geometry | Size (mm) | Tolerance |

Piezo Discs | Diameter: 3 to 200 |

Tolerance according to the piezoelectric elements Industrial standard. |

Thickness: 0.2-25 | ||

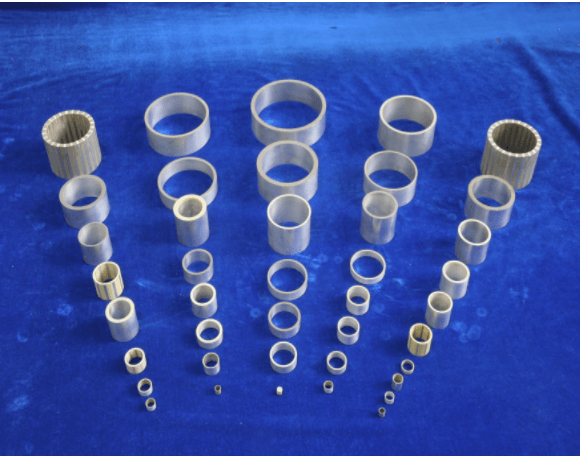

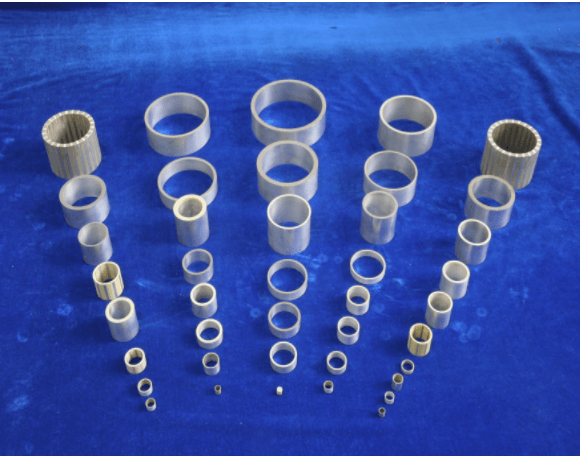

Piezo Tubes | Length: 1-100 | |

OD: 6-180 | ||

ID: 5-150 | ||

Wall: 0.5-15 | ||

Piezo Plates | Length: 1-200 | |

Width: 1-200 | ||

Thickness: 0.2-25 | ||

Piezo Sphere | OD: 6-160 | |

ID: 4-150 | ||

Wall: 1-10 | ||

Piezo Rings | OD: 3-180 | |

ID: 1-150 | ||

Thickness : 0.2-25 | ||

For All Sizes | Flatness | ± 0.03 |

Concentricity | ± 0.10 | |

Perpendicularity | ± 0.10 | |

Parallelism | ± 0.05 |

PZT Soft Material:

"Soft" PZT materials | The type of soft material | ||||||||

Properties | PSnN-5 | PLiS-51 | PZT-51 | PZT-52 | PZT-53 | PZT-5H | PZT-5X | ||

Dielectric Constant | ɛTr3 | 1600 | 2000 | 2200 | 2400 | 2600 | 3200 | 4500 | |

Coupling factor | KP | 0.6 | 0.62 | 0.62 | 0.63 | 0.64 | 0.68 | 0.7 | |

K31 | 0.35 | 0.35 | 0.35 | 0.35 | 0.36 | 0.38 | 0.4 | ||

K33 | 0.68 | 0.7 | 0.68 | 0.7 | 0.7 | 0.76 | 0.77 | ||

Kt | 0.5 | 0.52 | 0.5 | 0.5 | 0.5 | 0.52 | 0.53 | ||

Piezoelectric coefficient | d31 | 10-12m/v | -170 | -197 | -186 | -204 | -227 | -275 | -300 |

d33 | 10-12m/v | 400 | 450 | 500 | 520 | 550 | 620 | 750 | |

g31 | 10-3vm/n | -12 | -11.1 | -9.6 | -9.8 | -9.9 | -9.7 | -7.5 | |

g33 | 10-3vm/n | 28 | 25.4 | 25.6 | 24.5 | 23.9 | 22 | 18.8 | |

Frequency coefficients | Np | 2000 | 1920 | 1980 | 1980 | 1960 | 1900 | 1960 | |

N1 | 1466 | 1407 | 1451 | 1451 | 1437 | 1393 | 1437 | ||

N3 | 1825 | 1925 | 1900 | 1900 | 1755 | 1550 | 1800 | ||

Nt | 2100 | 2100 | 2150 | 2150 | 2150 | 2100 | 2200 | ||

Elastic compliance coefficient | Se11 | 10-12m2/n | 16.6 | 18 | 16.7 | 17 | 17.4 | 18 | 19 |

Machanical quality factor | Qm | 85 | 80 | 80 | 75 | 75 | 70 | 65 | |

Dielectric loss factor | Tg δ | % | 2 | 2 | 2 | 2 | 2 | 2 | 2 |

Density | ρ | g/cm3 | 7.5 | 7.5 | 7.6 | 7.6 | 7.6 | 7.5 | 7.5 |

Curie Temperature | Tc | °C | 350 | 345 | 270 | 270 | 270 | 230 | 165 |

Young's modulus | YE11 | <109N/m2 | 60 | 56 | 60 | 59 | 57.5 | 56 | 53 |

Poison Ratio | 0.36 | 0.36 | 0.36 | 0.36 | 0.36 | 0.36 | 0.39 | ||

PZT Hard Material:

Hard" PZT materials | PZT-41 | PZT-42 | PZT-43/4D | PZT-82 | PBaS-4 | ||

Dielectric Constant | ɛTr3 | 1050 | 1250 | 1420 | 1100 | 1900 | |

Coupling factor | KP | 0.58 | 0.58 | 0.58 | 0.52 | 0.59 | |

K31 | 0.32 | 0.33 | 0.34 | 0.3 | 0.34 | ||

K33 | 0.66 | 0.67 | 0.68 | 0.57 | 0.68 | ||

Kt | 0.48 | 0.48 | 0.48 | 0.4 | 0.49 | ||

Piezoelectric coefficient | d31 | 10-12m/v | -106 | -124 | -138 | -100 | -160 |

d33 | 10-12m/v | 260 | 280 | 300 | 240 | 380 | |

g31 | 10-3vm/n | -11.4 | -11.2 | -11 | -10.3 | -9.5 | |

g33 | 10-3vm/n | 28 | 25.3 | 24 | 25 | 22.6 | |

Frequency coefficients | Np | 2280 | 2200 | 2160 | 2280 | 2200 | |

N1 | 1671 | 1613 | 1583 | 1671 | 1613 | ||

N3 | 1950 | 1900 | 1875 | 1950 | 1850 | ||

Nt | 2250 | 2200 | 2200 | 2300 | 2200 | ||

Elastic compliance coefficient | Se11 | 10-12m2/n | 11.8 | 12.7 | 13.2 | 11.6 | 13.2 |

Machanical quality factor | Qm | 1000 | 800 | 600 | 1200 | 2200 | |

Dielectric loss factor | Tg δ | % | 0.3 | 0.4 | 0.5 | 0.3 | 0.5 |

Density | ρ | g/cm3 | 7.5 | 7.5 | 7.5 | 7.6 | 7.5 |

Curie Temperature | Tc | °C | 320 | 320 | 320 | 310 | 310 |

Young's modulus | YE11 | <109N/m3 | 85 | 79 | 76 | 86 | 76 |

Poison Ratio | 0.3 | 0.3 | 0.3 | 0.3 | 0.33 |

Package Details:

FAQ:

1.About piezoelectric ceramics material , what's the equivalent ceramic materials?

PZT Material Supplier | Navy Type I (PZT-4) | Navy Type II (PZT-5A) | Navy Type VI (PZT-5H) | Navy Type III (PZT-8) |

Piezo Hannas | P-41 | P-51 | P-5H | P-82 |

Morgan Matroc | PZT-4 | PZT-5A | PZT-5H | PZT-8 |

Channel Ind. | C5400 | C5500 | C5700 | C5800 |

EDO Corp. | EC-64 | EC-65 | EC-76 | EC-69 |

Keramos | K-270 | K-350 | K-278 | |

Transducer Products | LTZ-1 | LTZ-2 | LTZ-2H | |

Staveley Sensors | EBL1 | EBL2 | EBL3 | EBL4 |

2.What are the underwater acoustic application fields of piezoelectric ceramics?

Seabed exploration, sonar, hydorphone, NDT,beacon, imaging, galvanometer....

3.About piezoelectric ceramic transducer, which is the effect of using piezoelectric ceramics? ?

About piezoelectric ceramic transducers, which utilize the two major effects of piezoelectric ceramics, in particular, the transducers use the inverse piezoelectric effect when they emit, and they utilize positive piezoelectric effect when is receiving ,In turn, let this kind of transducer work and use normally.

High Sensitivity Soft Piezoelectric Ceramics Piezo Tube for Sonar

WuHan Piezohannas Tech.Co .,Ltd is a manufactuer of piezoelectric ceramics ,ultrasonic transducers with strong technology force.With a quality management system and research & development sector,our products are extensively used in most applications.

l. Piezo ceramic Description:

Geometry | Size (mm) | Tolerance |

Piezo Discs | Diameter: 3 to 200 |

Tolerance according to the piezoelectric elements Industrial standard. |

Thickness: 0.2-25 | ||

Piezo Tubes | Length: 1-100 | |

OD: 6-180 | ||

ID: 5-150 | ||

Wall: 0.5-15 | ||

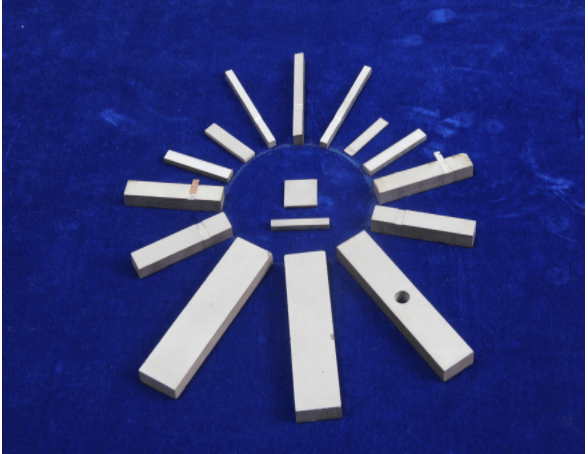

Piezo Plates | Length: 1-200 | |

Width: 1-200 | ||

Thickness: 0.2-25 | ||

Piezo Sphere | OD: 6-160 | |

ID: 4-150 | ||

Wall: 1-10 | ||

Piezo Rings | OD: 3-180 | |

ID: 1-150 | ||

Thickness : 0.2-25 | ||

For All Sizes | Flatness | ± 0.03 |

Concentricity | ± 0.10 | |

Perpendicularity | ± 0.10 | |

Parallelism | ± 0.05 |

PZT Soft Material:

"Soft" PZT materials | The type of soft material | ||||||||

Properties | PSnN-5 | PLiS-51 | PZT-51 | PZT-52 | PZT-53 | PZT-5H | PZT-5X | ||

Dielectric Constant | ɛTr3 | 1600 | 2000 | 2200 | 2400 | 2600 | 3200 | 4500 | |

Coupling factor | KP | 0.6 | 0.62 | 0.62 | 0.63 | 0.64 | 0.68 | 0.7 | |

K31 | 0.35 | 0.35 | 0.35 | 0.35 | 0.36 | 0.38 | 0.4 | ||

K33 | 0.68 | 0.7 | 0.68 | 0.7 | 0.7 | 0.76 | 0.77 | ||

Kt | 0.5 | 0.52 | 0.5 | 0.5 | 0.5 | 0.52 | 0.53 | ||

Piezoelectric coefficient | d31 | 10-12m/v | -170 | -197 | -186 | -204 | -227 | -275 | -300 |

d33 | 10-12m/v | 400 | 450 | 500 | 520 | 550 | 620 | 750 | |

g31 | 10-3vm/n | -12 | -11.1 | -9.6 | -9.8 | -9.9 | -9.7 | -7.5 | |

g33 | 10-3vm/n | 28 | 25.4 | 25.6 | 24.5 | 23.9 | 22 | 18.8 | |

Frequency coefficients | Np | 2000 | 1920 | 1980 | 1980 | 1960 | 1900 | 1960 | |

N1 | 1466 | 1407 | 1451 | 1451 | 1437 | 1393 | 1437 | ||

N3 | 1825 | 1925 | 1900 | 1900 | 1755 | 1550 | 1800 | ||

Nt | 2100 | 2100 | 2150 | 2150 | 2150 | 2100 | 2200 | ||

Elastic compliance coefficient | Se11 | 10-12m2/n | 16.6 | 18 | 16.7 | 17 | 17.4 | 18 | 19 |

Machanical quality factor | Qm | 85 | 80 | 80 | 75 | 75 | 70 | 65 | |

Dielectric loss factor | Tg δ | % | 2 | 2 | 2 | 2 | 2 | 2 | 2 |

Density | ρ | g/cm3 | 7.5 | 7.5 | 7.6 | 7.6 | 7.6 | 7.5 | 7.5 |

Curie Temperature | Tc | °C | 350 | 345 | 270 | 270 | 270 | 230 | 165 |

Young's modulus | YE11 | <109N/m2 | 60 | 56 | 60 | 59 | 57.5 | 56 | 53 |

Poison Ratio | 0.36 | 0.36 | 0.36 | 0.36 | 0.36 | 0.36 | 0.39 | ||

PZT Hard Material:

Hard" PZT materials | PZT-41 | PZT-42 | PZT-43/4D | PZT-82 | PBaS-4 | ||

Dielectric Constant | ɛTr3 | 1050 | 1250 | 1420 | 1100 | 1900 | |

Coupling factor | KP | 0.58 | 0.58 | 0.58 | 0.52 | 0.59 | |

K31 | 0.32 | 0.33 | 0.34 | 0.3 | 0.34 | ||

K33 | 0.66 | 0.67 | 0.68 | 0.57 | 0.68 | ||

Kt | 0.48 | 0.48 | 0.48 | 0.4 | 0.49 | ||

Piezoelectric coefficient | d31 | 10-12m/v | -106 | -124 | -138 | -100 | -160 |

d33 | 10-12m/v | 260 | 280 | 300 | 240 | 380 | |

g31 | 10-3vm/n | -11.4 | -11.2 | -11 | -10.3 | -9.5 | |

g33 | 10-3vm/n | 28 | 25.3 | 24 | 25 | 22.6 | |

Frequency coefficients | Np | 2280 | 2200 | 2160 | 2280 | 2200 | |

N1 | 1671 | 1613 | 1583 | 1671 | 1613 | ||

N3 | 1950 | 1900 | 1875 | 1950 | 1850 | ||

Nt | 2250 | 2200 | 2200 | 2300 | 2200 | ||

Elastic compliance coefficient | Se11 | 10-12m2/n | 11.8 | 12.7 | 13.2 | 11.6 | 13.2 |

Machanical quality factor | Qm | 1000 | 800 | 600 | 1200 | 2200 | |

Dielectric loss factor | Tg δ | % | 0.3 | 0.4 | 0.5 | 0.3 | 0.5 |

Density | ρ | g/cm3 | 7.5 | 7.5 | 7.5 | 7.6 | 7.5 |

Curie Temperature | Tc | °C | 320 | 320 | 320 | 310 | 310 |

Young's modulus | YE11 | <109N/m3 | 85 | 79 | 76 | 86 | 76 |

Poison Ratio | 0.3 | 0.3 | 0.3 | 0.3 | 0.33 |

Package Details:

FAQ:

1.About piezoelectric ceramics material , what's the equivalent ceramic materials?

PZT Material Supplier | Navy Type I (PZT-4) | Navy Type II (PZT-5A) | Navy Type VI (PZT-5H) | Navy Type III (PZT-8) |

Piezo Hannas | P-41 | P-51 | P-5H | P-82 |

Morgan Matroc | PZT-4 | PZT-5A | PZT-5H | PZT-8 |

Channel Ind. | C5400 | C5500 | C5700 | C5800 |

EDO Corp. | EC-64 | EC-65 | EC-76 | EC-69 |

Keramos | K-270 | K-350 | K-278 | |

Transducer Products | LTZ-1 | LTZ-2 | LTZ-2H | |

Staveley Sensors | EBL1 | EBL2 | EBL3 | EBL4 |

2.What are the underwater acoustic application fields of piezoelectric ceramics?

Seabed exploration, sonar, hydorphone, NDT,beacon, imaging, galvanometer....

3.About piezoelectric ceramic transducer, which is the effect of using piezoelectric ceramics? ?

About piezoelectric ceramic transducers, which utilize the two major effects of piezoelectric ceramics, in particular, the transducers use the inverse piezoelectric effect when they emit, and they utilize positive piezoelectric effect when is receiving ,In turn, let this kind of transducer work and use normally.

Products | About Us | News | Markets and Applications | FAQ | Contact Us